Fox River Successfully Achieves Pilot Plant Production of Merchant Grade Phosphoric Acid (MGA)

- Battery supply chain testing now moving to final stages

- High quality gypsum by-product may be eligible for industrial and agricultural uses

- Phosphate quality may be eligible for European market (low cadmium)

TORONTO, March 27, 2024 (GLOBE NEWSWIRE) -- Fox River Resources Corporation (the “Company” or “Fox River”) (CSE: FOX) is pleased to announce that the JESA Technologies Hemi Di Hydrate (“HDH”) Process has successfully transformed the Martison phosphate concentrate to a high-quality Merchant Grade Phosphoric Acid (“MGA”).

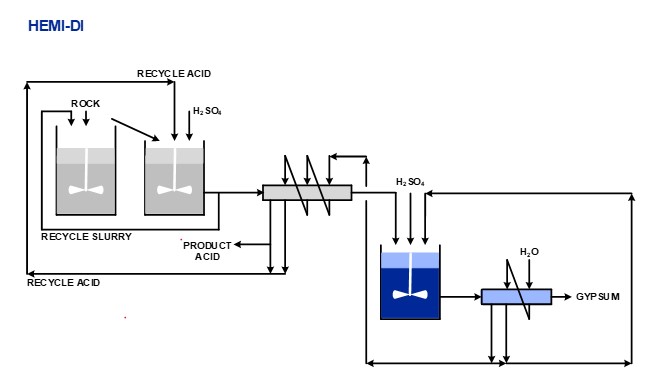

In Q3 2023, a 600-kilogram sample of apatite concentrate was sent to the facilities of JESA Technologies in Lakeland, Florida USA for the production of phosphoric acid using the JESA Technologies Hemi-Dihydrate (“HDH”) process. The feed rate of the rock feed blend and sulphuric acid were calculated to be at a specific reactor volume of 2M3/t/d P2O5. During the 160 hour continuous run, product samples of both the 40% P2O5 phosphoric acid and the gypsum were analyzed every three hours. The 40% P2O5 phosphoric acid was then concentrated to produce merchant grade acid (MGA). The clarification tests produced a low quantity of sludge.

Approximately 100 litres of MGA (54% P2O5) were produced for the purposes of testing its suitability for the production of purified phosphoric acid (“PPA”) used in the lithium iron phosphate (“LFP”) battery markets.

The PPA testing results are expected to be available by the end of Q3 2024.

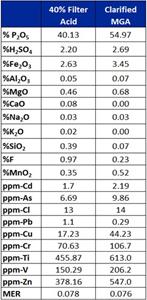

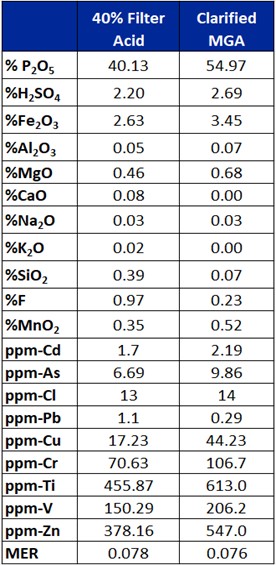

The main results of the MGA tests are summarized below:

- The phosphate concentrate used in the pilot plant contained 36.64% P2O5 with a MER of 0.089. The high-grade igneous concentrate was blended to assimilate the grade and MER, (level of impurities) used in the Preliminary Economic Study (PEA).

- Further grinding of the phosphate concentrate was not required.

- The operation of the pilot plant using the Martison phosphate rock was stable and quite easily operable in the JESA Technologies HDH process route.

- Efficiency (P2O5 recovery) at the pilot unit is high and above 99%.

- The total phosphate content found in the gypsum produced is low at less than 0.2% P2O5.

- Overall plant sizing, including the two filters, will be relatively compact due to the good filtration rates obtained.

- The MGA (54% P2O5) quality can be easily attained from the 40% P2O5 acid produced when processed using the JESA Technologies HDH process route.

- The MGA clarification tests produced very little sludge (0.68% solids w/w produced after 96 hrs).

- The sulphuric acid consumption used in the phosphate acidulation process was 2.46 tonnes, basis 100% H2SO4 per tonne of P2O5. This is lower than most sedimentary deposits and produces an economic advantage due to lower sulphuric acid consumption.

- The quantity of calcium sulphate generated by the process is 4.55 tonnes dihydrate (DH) per tonne of P2O5 produced.

- The impact of the JESA Technologies HDH process route on the environment is low compared to other phosphoric acid processes. This process produces a clean, low impurity, calcium sulphate (Gypsum).

- The calcium sulphate is of a quality that can possibly be used in the agriculture, construction, or cement industries. Further work will need to be conducted to confirm these markets.

- The cadmium content is less than 2 ppm in the 40% P2O5 phosphoric acid and less than 3 ppm in the 54% P2O5 MGA. This is important because it will allow the production of fertilizer products that meet the most stringent European cadmium content regulations.

Figures and Diagrams

Pilot plant set-up as shown in the sketch below.

Figure 1: JESA Technologies Process Route

Figure 2: 40% Filter Product Acid

Figure 3: Clarified MGA

Table 1: Analysis of 40% Filter Acid and Clarified MGA

Figure 4: Dihydrate Gypsum Cake

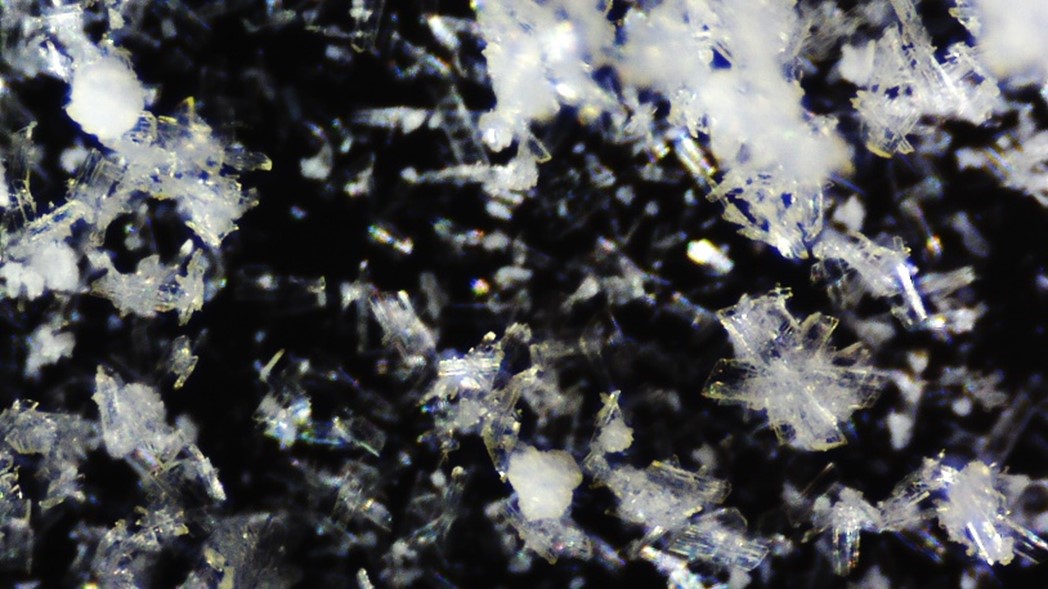

Figure 5: Dihydrate Gypsum Crystals

Technical Information

The scientific and technical disclosure for Fox River Resources included in this news release have been reviewed and approved by Mr. James Byrd. Mr. Byrd is a chemical engineer and a “Qualified Person” as defined by National Instrument 43-101 Standards of Disclosure for Mineral Projects and has verified the data disclosed in this news release.

ABOUT FOX RIVER

Fox River owns a 100% interest in the Martison Phosphate Project, located near Hearst, Ontario. The Martison Phosphate Project hosts the Anomaly A deposit which forms the basis for a positive preliminary economic assessment with an effective date of April 21, 2022. Additional information can be found at www.fox-river.ca or under Fox River’s profile on SEDAR.

For further information, please contact:

Stephen D. Case

President & Chief Executive Officer

Tel: (416) 972-9222

www.fox-river.ca

Neither the Canadian Securities Exchange nor its Regulation Services Provider (as that term is defined in the policies of the Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward-Looking Statements

Certain information set forth in this news release may contain forward-looking statements that involve substantial known and unknown risks and uncertainties, including, but not limited to, exploration results, potential mineralization, statements relating to mineral resources, and the Company’s plans with respect to the exploration and development of its properties. These forward-looking statements are subject to numerous risks and uncertainties, certain of which are beyond the control of Fox River Resources Corporation, including, but not limited to, the impact of general economic conditions, industry conditions, volatility of commodity prices, risks associated with the uncertainty of exploration results and estimates, currency fluctuations, dependency upon regulatory approvals, the uncertainty of obtaining additional financing, and exploration risk. Readers are cautioned that the assumptions used in the preparation of such information, although considered reasonable at the time of preparation, may prove to be imprecise and, as such, undue reliance should not be placed on forward-looking statements.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/819fa017-f6c4-4015-89e1-e9190fa909df

https://www.globenewswire.com/NewsRoom/AttachmentNg/56662c71-6679-4bc6-895c-4019204543c2

https://www.globenewswire.com/NewsRoom/AttachmentNg/96b37d5c-c41f-4b25-953c-5d74f0b8da43

https://www.globenewswire.com/NewsRoom/AttachmentNg/7690383f-83a7-4b66-b03b-115a683f5155

https://www.globenewswire.com/NewsRoom/AttachmentNg/d39a3632-ce3d-424a-bcae-7fcc5a1b4180

https://www.globenewswire.com/NewsRoom/AttachmentNg/a6edbe29-3681-4a0f-b0fa-3cbcf17ddcfc