Gen2 PUREVAP?,,? Proof of Concept Test Demonstrates Capacity to Produce Spherical Nano Powders From Silicon Metal for the Lithium-Ion Battery Market

MONTREAL, Jan. 15, 2020 (GLOBE NEWSWIRE) -- HPQ Silicon Resources Inc. (“HPQ” - “The Company”) TSX-V: HPQ; FWB: UGE; Other OTC : URAGF; (“HPQ”) would like to update shareholders on progress made by HPQ and PyroGenesis Canada Inc. (TSX-V: PYR) (“PyroGenesis”) regarding manufacturing Silicon Metal (Si) nano-powders for next generation Lithium (Li-ion) Si batteries.

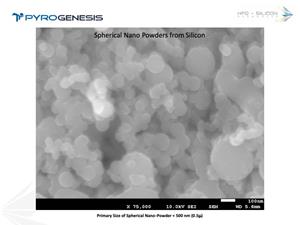

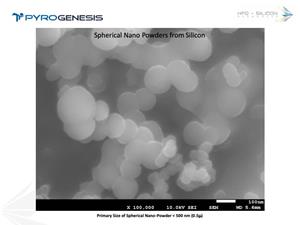

GEN2 PUREVAPTM USED TO SYNTHESIZE SPHERICAL NANO POWDERS (SIZE <0.5 µ) FROM SILICON (Si)

The PUREVAPTM Gen2 reactor was modified to test if it could produce Nano-powders. A key milestone was reached when the proof of concept test successfully produced spherical nano-powders from silicon metal as raw material, with a primary size <500 nanometre (<0.5 µ).

Scanning electron microscope (SEM) images taken of the spherical nano-powders produced by the GEN2 PUREVAPTM

Image A is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/e54d3d4f-276e-473a-b2f3-b336cdeb0698

Image B is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/d8c8a42a-3c2b-4e5e-86e3-d958f60c2523

SPHERICAL NANOSCALE SILICON POWDERS KEY TO HIGHER ENERGY DENSITY LI-ION BATTERIES

Spherical Silicon Metal Nano-Powders have been identified as a key factor that will allow the manufacturing of high-performance Li-ion batteries using Silicon Metal (Si) anodes needed to deliver on the research promises of an almost tenfold (10x) increase in the specific capacity of the anode, inducing a 20-40% gain in the energy density of Li-ion batteries. Current manufacturing methods for Silicon Metal Nano-Powders are expensive, not very scalable and not commercially feasible with US$ 30,000/kg1 selling prices. HPQ and PyroGenesis are working to change that with our new approach.

MASSIVE ENERGY STORAGE DEMAND CANNOT BE MET UNLESS SILICON ANODES REPLACE GRAPHITE

The Li-ion battery is the dominant technology in energy storage while graphite, a fairly low energy density material compared to other anode materials, is the dominant anode material in for Li-Ion batteries.

A graph accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/a443d48f-5db8-4da0-8072-dd53ea4317e3

Present anode technology limits the use of Silicon Metal (Si) powders to a blended form with graphite, resulting in less than 10 wt% Si in Li-ion batteries. This explains the limited performance improvement achieved to date.

A recent report by Wood Mackenzie Power projects that energy storage deployments are estimated to grow 1,300% from a 12 Gigawatt-hour market in 2018 to a 158 Gigawatt-hour market in 2024. This is why, even at these low content levels, demand for Silicon Metal powders is estimated to represent an addressable market of US $ 1B by 20222 expanding at a CAGR of 38.9% between 2019 – 2024.

HPQ AND PYROGENESIS WELL POSITIONED TO ASSUME FIRST MOVER ADVANTAGE IN THE MARKET

Building upon the success of the modified Gen2 PUREVAP™ proof of concept test, PyroGenesis is designing additional process improvements to the modified Gen2 PUREVAP™ Reactor in order to demonstrate the commercial potential of the high yield, low cost process we are developing to produce Spherical Silicon Metal (Si) nano-powders for the Li-ion batteries markets.

This represents a unique multibillion-dollar business opportunity that could subsequently lead to the wide scale adoption of our Material in the battery market. If this occurs, HPQ and PyroGenesis would then be well positioned to assume a dominant market position. In Q1 2020, the plan is to have the fully modified Gen2 PUREVAPTM reactor operational to validate that our approach both works and is scalable while also producing samples for industry participants and research institutions.

“PyroGenesis has a long the track record of taking high-technology projects from proof of concept to global commercial scalability, so if anybody has the knowhow to use the silicon metal produced by HPQ PUREVAP™QRR and make spherical Silicon Metal (Si) nano-powders for use as high-capacity anode materials in the next generations Li-ion batteries, it is them,” said Bernard Tourillon, President and CEO HPQ Silicon. “Silicon Metal’s potential to meet energy storage demand is undeniable and generating massive investments, as well as, serious industry interest, so our timing could not be better.”

“We are delighted by the PUREVAP™ Gen2’s recent test results from which it has established a very important proof of concept for the production of spherical nano powders for the Lithium-ion batteries market,” said M. P Peter Pascali, President and CEO of PyroGenesis Canada Inc. “The success of this testing paves the way for an interesting business opportunity for both PyroGenesis and HPQ. The goal is to significantly increase the performance of Li-ion batteries, currently in demand, using silicon metal (Si) anodes, at a competitive cost. The potential from the battery and energy storage markets alone is estimated, on first review, to be quite significant.”

About Silicon Metal

Silicon Metal (Si) is one of today’s strategic materials needed to fulfil the renewable energy revolution presently under way. Silicon does not exist in its pure state; it must be extracted from quartz, one of the most abundant minerals of the earth’s crust and other expensive raw materials in a carbothermic process.

About HPQ Silicon

HPQ Silicon Resources Inc. (TSX-V: HPQ) is developing, with PyroGenesis Canada Inc. (TSX-V: PYR), a high-tech company that designs, develops, manufactures and commercializes plasma base processes, the innovative PUREVAPTM “Quartz Reduction Reactors” (QRR), a truly 2.0 Carbothermic process (patent pending), which will permit the One Step transformation of Quartz (SiO2) into High Purity Silicon (Si) at prices that will propagate its considerable renewable energy potential. The Gen3 PUREVAPTM QRR pilot plant that will validate the commercial potential of the process is scheduled to start during Q1 2020.

HPQ, working with PyroGenesis, is also developing a process that can take the High Purity Silicon (Si) made by the PUREVAPTM and manufacture Spherical Silicon Metal nano-powders for Next Gen Li-ion batteries. During Q1 2020, the plan is to validate our game changing manufacturing approach using a modified Gen2 PUREVAPTM reactor to produce spherical Silicon Metal (Si) nano-powders samples for industry participants and research institutions’.

Concurrently, HPQ is also working with industry leader Apollon Solar to develop a manufacturing capability that uses the High Purity Silicon (Si) made with the PUREVAP™ to make Porous silicon wafers needed for solid-state Li-ion batteries. The first Silicon wafer should be ready to be ship for testing to a battery manufacture (under NDA) during Q1 2020.

Finally, with Apollon Solar, we are also looking into developing a metallurgical pathway of producing Solar Grade Silicon Metal (SoG Si) that will take full advantage of the PUREVAPTM QRR one-step production of Silicon (Si) material of 4N+ purity with low boron count (< 1 ppm).

All in all, HPQ focus is becoming the lowest cost producer of Silicon Metal (Si), High Purity Silicon Metal (Si), Spherical Si nano-powders for Next Gen Li-ion batteries, Porous Silicon Wafers for Solid states Li-ion batteries, Porous Silicon Powders for Li-ion batteries and Solar Grade Silicon Metal (SoG-Si).

This News Release is available on the company's CEO Verified Discussion Forum, a moderated social media platform that enables civilized discussion and Q&A between Management and Shareholders.

Disclaimers:

The Corporation’s interest in developing the PUREVAP™ QRR and any projected capital or operating cost savings associated with its development should not be construed as being related to the establishing the economic viability or technical feasibility of any of the Company’s Quartz Projects.

This press release contains certain forward-looking statements, including, without limitation, statements containing the words "may", "plan", "will", "estimate", "continue", "anticipate", "intend", "expect", "in the process" and other similar expressions which constitute "forward-looking information" within the meaning of applicable securities laws. Forward-looking statements reflect the Company's current expectation and assumptions and are subject to a number of risks and uncertainties that could cause actual results to differ materially from those anticipated. These forward-looking statements involve risks and uncertainties including, but not limited to, our expectations regarding the acceptance of our products by the market, our strategy to develop new products and enhance the capabilities of existing products, our strategy with respect to research and development, the impact of competitive products and pricing, new product development, and uncertainties related to the regulatory approval process. Such statements reflect the current views of the Company with respect to future events and are subject to certain risks and uncertainties and other risks detailed from time-to-time in the Company's on-going filings with the security’s regulatory authorities, which filings can be found at www.sedar.com. Actual results, events, and performance may differ materially. Readers are cautioned not to place undue reliance on these forward-looking statements. The Company undertakes no obligation to publicly update or revise any forward-looking statements either as a result of new information, future events or otherwise, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

For further information contact

Bernard J. Tourillon, Chairman, President and CEO Tel (514) 907-1011

Patrick Levasseur, Vice-President and COO Tel: (514) 262-9239

http://www.hpqsilicon.com Email: Info@hpqsilicon.com

1 Source: Quotation from a producer (Confidential), Media article

2 Source Marketandmakerts.com