Nicola Mining Announces Test Results from Magnetite Recovery Which Results in an Increase in Copper Equivalent Grades of up to 34%

Vancouver, British Columbia--(Newsfile Corp. - February 19, 2019) - Nicola Mining Inc. (TSXV: NIM) (the "Company" or "Nicola") is pleased to announce the results of a preliminary metallurgical testing program and the significance of a copper-magnetite grade equivalent ("CuEq") at its wholly-owned New Craigmont Project (the "Project"), located 14 km from the city of Merritt, BC.

Nicola contracted ALS Metallurgy's Kamloops[1] laboratory to perform magnetic separation and froth floatation testing on samples collected from a number of selected diamond drill and reverse circulation drill holes ("RC").

A total of thirty-nine samples were classified into low-grade ("LG") copper and high-grade copper ("HG") composites that reflect mineralization grades encountered at the Project. The composites were tested using a Davis Tube[2] for magnetite separation. Composite samples were then tested by froth floatation to determine copper recovery. The tailings from the froth floatation was then re-tested using the Davis Tube test to determine the iron ("Fe") recovery after copper extraction (Figure 1).

Figure 1: Workflow of composite samples[1]

To view an enhanced version of this graphic, please visit:

https://orders.newsfilecorp.com/files/4873/42897_1acf4d2624585933_001full.jpg

Metallurgical testing was conducted to provide a CuEq value, based on recoverable magnetite (Fe₃O₄) associated with Cu mineralization, as not all Fe grades can be attributed to magnetite. ALS Metallurgy provided the Company its findings in the Metallurgy Testing for Nicola Mining - KM8541 report[3], which is available on the Company's website[4] and filed on Sedar.

The composite samples created are described below:

Low-grade Copper Composite: Feed assays on the LG composite were conducted by ALS and returned grades of 0.27% Cu and 5.1% Fe.

- The presence of magnetite in low-grade material provided an economic contribution of approximately 34% and an increase in CuEq of approximately 0.09%.

High-grade Copper Composite: Feed assays on the HG composite were conducted by ALS and returned grades of 3.26% copper ("Cu") and 11.4% iron ("Fe").

- The presence of magnetite in high-grade material provided an economic contribution of approximately 11% and an increase in CuEq of approximately 0.35%

The reduction in economic contribution and increase in CuEq in the HG composite, relative to the LG composite, is attributed to higher grades and economic value of Cu and magnetite in the HG material. Preliminary metallurgical results indicate average recoverable magnetite to be equivalent to 25% of assayed Fe. As expected, results also indicate that higher magnetite recovery is associated with increased Cu grades.

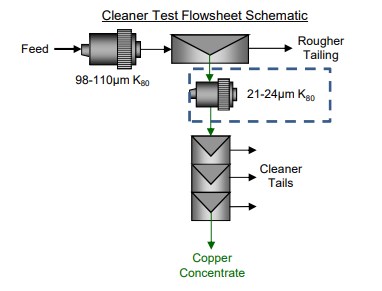

The froth floatation test of the two composite samples aimed to evaluate the percentage of recoverable copper held within each composite using rougher and cleaner techniques. Following floatation simulations, a second David Tube test was completed on the tails from each composite to confirm the amount of recoverable magnetite from Fe after copper had been extracted.

The results of the froth floatation tests on the composite samples demonstrate that copper may be economically recovered. Approximately 96% of Cu was recovered from HG composite with no significant difference between the recovery from rougher and cleaner results. Approximately 81% of Cu was recovered from LG composite, with limited improved Cu recovery from regrinding (Figure 2).

Figure 2: Rougher and Cleaner Test Results[3]

To view an enhanced version of this graphic, please visit:

https://orders.newsfilecorp.com/files/4873/42897_1acf4d2624585933_002full.jpg

Understanding the amount of recoverable magnetite from iron is important because magnetite, which is sold via contract, sells between US$100 - US$300 per metric tonne[5], whereas iron spot prices are closer to US$80.0 per metric tonne[6].

From these results, a CuEq can be calculated for magnetite by applying the magnetite recovery ratio from iron for both the low-grade and high-grade material to estimate the magnetite content of a given sample and calculate copper grade equivalent based on current market prices.

Based on these results, for the LG composite the economic contribution of magnetite accounted for 34% of the overall CuEq, which increased by from 0.27% Cu to 0.36% CuEq (an increase of approximately 0.09% CuEq). The contribution and increased CuEq could be significant in cutoff grades and future NI 43 101 resource estimates.

The Company remains focused on high-grade copper exploration, of which the high-grade CuEq is most characteristic. Economic contribution of magnetite in the HG composite accounted for 11% of the overall CuEq, which increased from 3.26% Cu to 3.61% CuEq (an increase of approximately 0.35% CuEq).

Peter Espig, Chief Executive Officer, commented, "the Company has yet to issue several drill results from its 2018 Exploration Program because we were waiting for the results as described in the 124-page Metallurgy Testing for Nicola Mining report. The historic Craigmont Copper Mine operated for twenty-one years, prior to closing in 1982 because of $0.60 lb. copper prices. Operations then shifted to twenty-one years of magnetite production, which focused on extracting magnetite from historic tailings. It's logical to combine the economic value of both copper and magnetite for this project. Going forward, exploration results will include CuEq grades."

Scientific and Technical Information

All information of a scientific or technical nature contained in this document, including sampling, analytical and test data has been reviewed and approved by Kevin Wells, P. Geo., a consulting Geologist to Nicola Mining. Wells is a Qualified Person as defined by National Instrument 43-101 - Standards of Disclosure for Mineral Projects.

Sample Preparation, Analysis and Quality Assurance/Quality Control

Nicola Mining applies a thorough quality assurance/quality control program at the New Craigmont Project compliant with industry best practices. A qualified geoscientist has logged and sampled all core and samples have been delimited according to lithologic, alteration and mineralization characteristics. This includes systematic insertion of blank, duplicate and certified reference materials into the sample batches by Nicola's geological staff. Core is then halved, where the

sample is placed in a labelled sample bag with sample tag and the other half of the core is retained at the Craigmont property as a physical record. All results included in this release have passed the QA/QC procedures as described above and have been reviewed by Kevin Wells, P.Geo. There are no known factors that could materially affect the reliability of data collected and verified. No quality assurance/quality control issues have been identified to date.

About Nicola Mining

Nicola Mining Inc. is a junior mining company listed on the TSX Venture Exchange and is in the process of recommencing mill feed processing operations at its 100% owned state-of-the-art mill and tailings facility, located near Merritt, British Columbia. It has already signed four mill profit share agreements with high grade gold producers. The fully-permitted mill can process both gold and silver mill feed via gravity and flotation processes. The Company also owns 100% of Treasure Mountain, a high-grade silver property, and an active gravel pit that is located adjacent to its milling operations.

About New Craigmont Property

In November of 2015, Nicola became the first group in decades to consolidate ownership of the New Craigmont Project (the "Property") and has been actively conducting mineral exploration since. The Property is a wholly-owned copper property with an active mine permit (M-68), located 33 km south of the world-class Highland Valley porphyry district. It lies at the southern contact between the Nicola Group rocks and Guichon Creek batholith, of which the latter is known to be a precursor to mineralization at Highland Valley.

There are currently no mineral resource estimates on the Property. Historical "non-NI 43-101" resource calculations are recorded in internal memos and geological reports for Placer Development Ltd. An internal memo[7] estimated 60,000,000 pounds (27,000 metric tonnes) of >1.5% copper ore remained unmined from an original ore estimate of 27,754,000 short tons (25,178,005 metric tonnes) of copper grading 1.79%, following mine closure. A mineralized zone (Body No. 3) is known to contain an estimated 1,290,000 tons (1,170,268 metric tonnes) of copper ore grading 1.53% copper, with a 0.7% copper cut-off grade[8] and a 20-foot mining width between drill sections 6565E and 8015E. During mine closure a comprehensive report highlighted a 60.0 million tonne halo grading greater than 0.4% surrounding the western extension of the high-grade underground ore body[9].

It should be noted that these historical estimates do not meet the requirements needed to conform to National Instrument 43-101 standards. The Company notes that an independent Qualified Person has not done sufficient work to verify and classify the historical estimates as current mineral resources and is therefore not treating the historical estimates as current mineral resources or mineral reserves. For further details on the Property, see the technical report entitled "Technical Report on the Thule Copper- Iron Property, Southern British Columbia, Canada", filed on May 8, 2013 on Sedar at www.sedar.com.

On behalf of the Board of Directors

"Peter Espig"

Peter Espig

CEO & Director

For additional information

Contact: Peter Espig

Phone: (778) 385-1213

Email: info@nicolamining.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

[1] ALS Kamloops is a subsidiary of ALS Global, leader in providing laboratory testing, inspection, certification and verification solutions. https://www.alsglobal.com/

[2] A Davis Tube is a laboratory instrument designed to separate small samples of strongly magnetic ores into strongly magnetic and weakly magnetic fractions

[3] Roulston, D. (Feb. 12, 2019) Metallurgical Testing for Nicola Mining - KM8541 Report, ALS Metallurgy

[4] Website Link: http://nicolamining.com/wp-content/uploads/2019/02/KM5841-Report.pdf

[5] Pricing Example: https://www.alibaba.com/showroom/magnetite-prices.html

[6] Source for Iron Spot Price: https://ycharts.com/indicators/iron_ore_spot_price_any_origin

[7] Bristow, J.F. (Jul. 22, 1985) Internal memo: Continued Exploration at Craigmont Mines Limited's Merritt Property.

[8] Bristow, J.F. (Oct. 30, 1985) Internal memo: Ore Reserves - No. 3 Orebody

[9] Bristow, J.F. (Apr. 24, 1968) The Geology of Craigmont Mines

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/42897