TMAC Announces Growth of Doris BTD Extension Zone and First Results from Doris Regional Program

TMAC Resources Inc. (TSX:TMR) (“TMAC” or the “Company”) is pleased to provide an interim exploration update including surface exploration drilling results at Doris and initial drilling results from the Doris regional program, including high grade gold intercepts within 15 metres of surface.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190814005408/en/

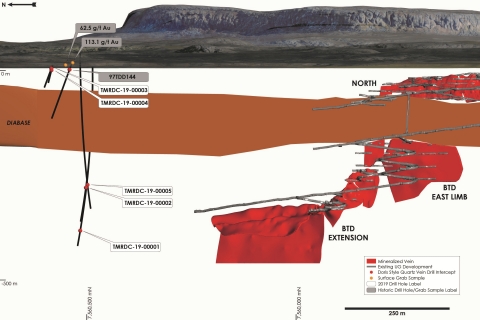

Figure 1: Doris longitudinal section showing the Doris Valley surface drilling relative to the BTD Extension zone. (Graphic: Business Wire)

DORIS BTD EXTENSION (DRILLING FROM UNDERGROUND) |

|

|

193.3 g/t Au over 1.8 metres |

And |

42.0 g/t Au over 0.6 metres |

And |

333.0 g/t Au over 0.6 metres |

|

15.6 g/t Au over 4.4 metres |

|

105.8 g/t Au over 1.5 metres |

|

110.8 g/t Au over 10.8 metres |

And |

7.5 g/t Au over 3.1 metres |

|

|

DORIS VALLEY HIGHLIGHTS (DRILLING FROM SURFACE) |

|

|

3.7 g/t Au over 0.4 metres |

And |

7.7 g/t Au over 7.5 metres |

Including |

11.8 g/t Au over 4.3 metres |

|

5.3 g/t Au over 4.8 metres |

Including |

12.5 g/t Au over 1.6 metres |

|

9.0 g/t Au over 8.5 metres |

Including |

15.4 g/t Au over 2.3 metres |

|

4.6 g/t Au over 1.3 metres |

And |

97.6 g/t Au over 0.3 metres |

Jason Neal, President and Chief Executive Officer of TMAC, stated, “We continue to have strong drilling results in the growing Doris BTD Extension zone, including in one hole 110.8 grams per tonne of gold over 10.8 metres. Additionally, initial drill results in a new zone we are calling Doris Valley, as part of our Doris regional program, are intriguing and we are evaluating our follow up strategy. At Doris Valley, assays from two holes in the vicinity of good surface grab samples included promising intercepts within the first 15 metres from surface. The first encountered 9.0 grams per tonne of gold over 8.5 metres including 15.4 grams per tonne of gold over 2.3 metres and a second had 5.3 grams per tonne of gold over 4.8 metres including 12.5 grams per tonne of gold over 1.6 metres. There is obviously more work required to follow up on this initial success, but this highlights the potential to grow our mineral inventory through even modest exploration investment.”

DORIS – EXPLORATION DRILLING

Subsequent to the July 15, 2019 second quarter exploration news release, surface exploration drilling continued at Doris, north of the known deposit in the Doris Valley. Near surface drilling was targeted below historical surface outcrop samples, which included 62.5 grams per tonne of gold and 113.1 grams per tonne of gold and drilling at depth was targeted 325 metres north along the potential strike of the Doris BTD Extension zone. To date, five holes have intersected the Doris deposit stratigraphy, with mineralized quartz veins at the Fe-Ti Tholeiite – Mg Tholeiite contact suggesting the Doris BTD stratigraphy continues at least 375 metres along strike to the north. Highlights from assays received from initial drilling include near surface drill hole TMRDC-19-00004 returning 9.0 grams per tonne of gold over 8.5 metres, including 15.4 grams per tonne of gold over 2.3 metres, and deeper drill hole TMRDC-19-00002 returning 7.7 grams per tonne of gold over 7.5 metres, including 11.8 grams per tonne of gold over 4.3 metres with visible gold noted. Assay results from the initial five drill holes are summarized in Table 1 and drill hole locations are illustrated in Figure 1. Additional drilling is required to determine the relationship to the known Doris Deposit, and if this a continuation of Doris North BTD Extension, a fault offset block, or a new mineralized zone. These results represent a significant step-out from the currently defined mineral resources and increases our confidence in the long-term sustainability of Doris operations.

Figure 1: Doris longitudinal section showing the Doris Valley surface drilling relative to the BTD Extension zone.

Also, at Doris mine, underground expansion and infill drilling is ongoing on the high-grade Doris BTD Extension zone, and additional assays have been received since the July 15, 2019 news release. Highlights from the underground expansion drilling program include drill hole TMDBE-19-50046 returning 193.3 grams per tonne of gold over 1.8 metres, and 42.0 grams per tonne of gold over 0.6 metres and 333.0 grams per tonne of gold over 0.6 metres, and drill hole TMDBE-19-50501 returning 105.8 grams per tonne of gold over 1.5 metres. Highlights from infill drilling at the south end of the zone, near the current underground access development include drill hole TMDBE-19-50507 returning 110.8 grams per tonne of gold over 10.8 metres and 7.5 grams per tonne of gold over 3.1 metres. Assay results for BTD Extension drill holes received since the previous news release are summarized in Table 2, and drill hole locations are illustrated in Figure 2. Underground infill and expansion drilling on the BTD Extension will continue through the remainder of 2019.

Figure 2: Doris BTD Extension gold grade contours based on Q2 drilling and locations of additional Q3 drill holes. Refer to figure 1 for location of the BTD Extension zone relative to the surface exploration drilling.

Table 1: Doris Valley surface exploration diamond drilling intersections.

Doris Valley Surface Exploration - TMAC 2019 Intersections |

||||||||

DRILL HOLE |

ZONE |

AZIMUTH

|

DIP

|

Inclusion |

FROM

|

TO

|

CORE

|

ASSAY

|

TMRDC-19-00001 |

Doris Valley |

270.0 |

-52.0 |

|

431.00 |

431.73 |

0.73 |

7.91 |

|

|

|

|

And |

502.40 |

506.45 |

4.05 |

6.52 |

|

|

|

|

Including |

502.40 |

505.44 |

3.04 |

8.53 |

TMRDC-19-00002 |

Doris Valley |

270.0 |

-48.0 |

|

322.13 |

322.59 |

0.46 |

3.70 |

|

|

|

|

And |

387.50 |

394.98 |

7.48 |

7.72 |

|

|

|

|

Including |

391.84 |

392.19 |

4.28 |

11.80 |

TMRDC-19-00003 |

Doris Valley |

294.0 |

-47.0 |

|

7.66 |

12.50 |

4.84 |

5.28 |

|

|

|

|

Including |

8.00 |

9.58 |

1.58 |

12.45 |

TMRDC-19-00004 |

Doris Valley |

294.0 |

-60.0 |

|

6.50 |

15.00 |

8.50 |

8.96 |

|

|

|

|

Including |

9.80 |

12.10 |

2.30 |

15.40 |

TMRDC-19-00005 |

Doris Valley |

94.0 |

-64.0 |

And |

317.00 |

318.30 |

1.30 |

4.59 |

|

|

|

|

And |

369.21 |

369.54 |

0.33 |

97.60 |

(1) True widths vary depending on the dip of the drill hole and orientation of the quartz veins and are unknown at this time.

Table 2: Doris BTD Extension Q3 exploration drilling intersections.

Doris BTD Extension - TMAC 2019 Intersections |

|||||||||

DRILL HOLE |

ZONE |

AZIMUTH

|

DIP

|

Inclusion |

FROM

|

TO (m) |

CORE

|

ASSAY

|

CAPPED

|

TMDBE-19-50045 |

BTD Extension |

145° |

-50° |

|

34.80 |

35.50 |

0.70 |

1.55 |

|

|

|

|

|

and |

190.22 |

196.17 |

5.95 |

2.71 |

|

TMDBE-19-50046 |

BTD Extension |

158° |

-24° |

|

77.14 |

78.00 |

1.78 |

193.33 |

48.38 |

|

|

|

|

and |

82.40 |

82.95 |

0.55 |

42.00 |

|

|

|

|

|

and |

87.84 |

88.44 |

0.60 |

333.00 |

100.00 |

TMDBE-19-50147 |

BTD Extension |

164.0 |

-35.0 |

|

51.00 |

55.42 |

4.42 |

0.58 |

|

TMDBE-19-50149 |

BTD Extension |

130.0 |

-30.0 |

|

52.88 |

54.00 |

1.12 |

24.80 |

|

|

|

|

|

and |

63.05 |

63.52 |

0.47 |

265.00 |

100.00 |

|

|

|

|

and |

72.32 |

72.82 |

0.50 |

70.30 |

|

TMDBE-19-50150 |

BTD Extension |

130.0 |

-45° |

|

173.56 |

175.69 |

2.13 |

0.36 |

|

TMDBE-19-50151 |

BTD Extension |

114.0 |

-38.0 |

|

55.00 |

55.60 |

0.60 |

12.65 |

|

|

|

|

|

and |

60.86 |

62.03 |

1.17 |

43.00 |

|

TMDBE-19-50500 |

BTD Extension |

135.0 |

-22.0 |

|

77.00 |

81.39 |

4.39 |

15.63 |

|

TMDBE-19-50501 |

BTD Extension |

116.0 |

-26.0 |

|

70.20 |

71.68 |

1.48 |

105.76 |

100.00 |

TMDBE-19-50506 |

BTD Extension |

146.0 |

-44.0 |

|

35.00 |

35.78 |

0.78 |

0.49 |

|

TMDBE-19-50507 |

BTD Extension |

132.0 |

-20.0 |

|

90.31 |

101.10 |

10.79 |

110.77 |

62.23 |

|

|

|

|

including |

92.30 |

98.45 |

6.15 |

168.27 |

83.10 |

|

|

|

|

and |

106.34 |

109.46 |

3.12 |

7.46 |

|

SAMPLE PREPARATION, ANALYSIS AND QUALITY ASSURANCE/QUALITY CONTROL

For the Doris drilling campaigns, samples were prepared at ALS Laboratories in Yellowknife, Northwest Territories and assayed at their Vancouver, British Columbia laboratory (an ISO/IEC 17025 accredited lab for gold analysis). Analysis for gold is completed on sawn half-core samples (NQ) using 50 gram fire assay with atomic absorption (AAS) finish. Samples with higher grade gold (greater than100 grams per tonne) are re-assayed using the pulp and fire assay with gravimetric finish procedures. Samples with visible gold and surrounding samples are analyzed using screen metallics (1,000 grams of material is screened to 100 microns, with all +100 micron material analyzed and two samples of -100 micron analyzed by 50 gram fire assay with AAS finish, results are averaged based on weight). Chip samples and select drill hole samples from Doris were prepared and analyzed at the internal laboratory located at the Doris mine site (non accredited lab), operated by SGS SA. Analysis for gold is completed using 30 gram fire assay with atomic absorption (AAS) finish. Samples with higher grade gold (greater than10 grams per tonne) are re-assayed using the pulp and fire assay with gravimetric finish. Samples with visible gold are selected to go directly to fire assay with gravimetric finish. The Company control checks include the insertion of standard reference materials and blank samples to monitor the precision and accuracy of the assay data. For a complete description of TMAC’s sample preparation, analytical methods and QA/QC procedures refer to the 2018 Annual Information Form dated March 11, 2019 and filed on TMAC’s profile at www.sedar.com.

SCIENTIFIC AND TECHNICAL INFORMATION

Information of a scientific or technical nature in respect of the Hope Bay property, other than new information related to Doris mine development, is based upon the Hope Bay Technical Report, as filed on TMAC’s profile at www.sedar.com. Scientific and technical information contained in this document was reviewed and approved by David King, P.Geo., Vice President, Exploration and Geoscience of TMAC, who is a “Qualified Person” as defined by National Instrument 43-101 – Standards of Disclosure for Mineral Projects.

ABOUT TMAC RESOURCES INC.

TMAC Resources operates Hope Bay located in Nunavut, Canada. The property and operations are remote but not isolated, serviced by both a port and airstrip. Hope Bay is an 80 km by 20 km Archean greenstone belt that has been explored by BHP, Miramar, Newmont and TMAC over a period spanning more than 30 years. In that time, more than $1.5 billion of sunk expenditures have been expended in exploration, evaluation, surface infrastructure and mine and process plant development. TMAC began producing gold in early 2017 from Doris, its first mine at Hope Bay, and processed gold at the Doris Plant which originally had nameplate capacity of 1,000 tonnes per day and expanded to 2,000 tonnes per day midway through in 2018. Hope Bay has 4.8 million oz of measured & indicated resources at Doris, Madrid and Boston deposits, largely within 350 metres of surface, with the potential to grow these established deposits considerably at depth, and then grow resources further through the prioritized exploration of the other more than 90 identified regional targets. TMAC is now permitted to produce from Madrid and Boston.

FORWARD-LOOKING INFORMATION

This release contains “forward-looking information” within the meaning of applicable securities laws that is intended to be covered by the safe harbours created by those laws. “Forward-looking information” includes statements that use forward-looking terminology such as “may”, “will”, “expect”, “anticipate”, “believe”, “continue”, “potential” or the negative thereof or other variations or comparable terminology.

“Forward-looking information” is not a guarantee of future performance and management bases forward-looking statements on a number of estimates and assumptions at the date the statements are made. Furthermore, such “forward-looking information” involves a variety of known and unknown risks, uncertainties and other factors, which may cause the actual plans, intentions, activities, results, performance or achievements expressed or implied. See “Risk Factors” in the Company’s Annual Information Form dated March 11, 2019 filed on SEDAR at www.sedar.com for a discussion of these risks.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190814005408/en/