West African Resources intercepts 25m at 15.03 g/t Au including 5.5m at 40.42 g/t Au at M1 South

SUBIACO, AUSTRALIA / ACCESSWIRE / November 26, 2018 / Gold developer West African Resources Limited (ASX: WAF; TSX-V: WAF) is pleased to report extensive visible gold has been intercepted in the deepest hole drilled to date at the Sanbrado Gold Project, Burkina Faso.

Highlights

- High grade intercept of 25m at 15.03 g/t Au from 862m including;

- 5.5m at 40.42 g/t Au from 863.5m

- 1.5m at 26.02 g/t Au from 879m

- 0.5m at 71.80 g/t Au from 886m

- New intercept located 220m vertical beneath existing Probable Ore Reserves

- Adds potential to extend the M1 South underground mine life to 7.5 years

- Drilling ongoing with two rigs on site infilling and extending high-grade gold mineralisation

Managing Director Richard Hyde commented:

''The 1km step-out hole beneath M1 South Mineral Reserves has intercepted 25m grading 15.03 g/t gold including 5.5m at 40.42 g/t gold. Success in our deepest hole to date demonstrates potential to extend the M1 South underground mine life and increase annual production in years 4 to 8.

''The Company remains on track to finalise a debt funding package for the development of Sanbrado by the end of Q4 2018, and will complete an optimised feasibility study incorporating resource and reserve updates and increased plant throughput, which will deliver higher annual gold production, by the end of Q1 2019.''

M1 South Drilling Program

As reported earlier this month (ASX/TSXV: 15/11/18) step down drilling in TAN18-DD228 has intercepted extensive high-grade gold more than 220m beneath existing Probable Reserves at M1 South. Table 1 shows individual 0.5m assays through the entire mineralised zone in TAN18-DD228. Also photos 1 and 2 show high grade visible gold for samples that returned 155 g/t Au and 188 g/t Au.

Table 1: M1 South: TAN18-DD228 1km hole

Main Zone 862m to 887m

| From (m) | To (m) | Sample ID | Au g/t | From (m) | To (m) | Sample ID | Au g/t | |

| 860 | 860.5 | 310747 | 0.03 | 880 | 880.5 | 310794 | 34.00 | |

| 860.5 | 861 | 310748 | 0.01 | 880.5 | 881 | 310795 | 6.49 | |

| 861 | 861.5 | 310749 | 0.03 | 881 | 881.5 | 310796 | 0.61 | |

| 861.5 | 862 | 310750 | 0.78 | 881.5 | 882 | 310797 | 0.20 | |

| 862 | 862.5 | 310751 | 2.53 | 882 | 882.5 | 310798 | 0.61 | |

| 862.5 | 863 | 310752 | 1.04 | 882.5 | 883 | 310799 | 0.32 | |

| 863 | 863.5 | 310753 | 0.27 | 883 | 883.5 | 310802 | 0.26 | |

| 863.5 | 864 | 310755 | 31.80 | 883.5 | 884 | 310803 | 0.83 | |

| 864 | 864.5 | 310756 | 0.98 | 884 | 884.5 | 310804 | 13.90 | |

| 864.5 | 865 | 310757 | 1.14 | 884.5 | 885 | 310805 | 1.66 | |

| 865 | 865.5 | 310758 | 155.00 | 885 | 885.5 | 310807 | 0.44 | |

| 865.5 | 866 | 310759 | 13.90 | 885.5 | 886 | 310808 | 5.40 | |

| 866 | 866.5 | 310762 | 4.99 | 886 | 886.5 | 310809 | 71.80 | |

| 866.5 | 867 | 310763 | 0.32 | 886.5 | 887 | 310810 | 2.14 | |

| 867 | 867.5 | 310764 | 7.90 | 887 | 887.5 | 310811 | 1.29 | |

| 867.5 | 868 | 310765 | 4.73 | 887.5 | 888 | 310812 | 0.57 | |

| 868 | 868.5 | 310766 | 188.00 | 888 | 888.5 | 310813 | 0.28 | |

| 868.5 | 869 | 310767 | 35.90 | 888.5 | 889 | 310814 | 0.17 | |

| 869 | 869.5 | 310768 | 2.15 | 889 | 889.5 | 310815 | 0.03 | |

| 869.5 | 870 | 310769 | 6.72 | 889.5 | 890 | 310816 | 0.04 | |

| 870 | 870.5 | 310771 | 17.80 | 890 | 890.5 | 310817 | 0.03 | |

| 870.5 | 871 | 310772 | 4.28 | 890.5 | 891 | 310818 | 0.03 | |

| 871 | 871.5 | 310773 | 5.09 | 891 | 891.5 | 310819 | 0.02 | |

| 871.5 | 872 | 310774 | 3.29 | 891.5 | 892 | 310822 | 0.03 | |

| 872 | 872.5 | 310775 | 1.18 | 892 | 892.5 | 310823 | 0.33 | |

| 872.5 | 873 | 310776 | 12.00 | 892.5 | 893 | 310824 | 0.40 | |

| 873 | 873.5 | 310777 | 25.90 | 893 | 893.5 | 310825 | 0.01 | |

| 873.5 | 874 | 310778 | 12.00 | 893.5 | 894 | 310826 | 1.08 | |

| 874 | 874.5 | 310779 | 3.23 | 894 | 894.5 | 310827 | 0.91 | |

| 874.5 | 875 | 310782 | 5.25 | 894.5 | 895 | 310828 | 0.06 | |

| 875 | 875.5 | 310783 | 15.90 | 895 | 895.5 | 310829 | 1.09 | |

| 875.5 | 876 | 310784 | 2.28 | 895.5 | 896 | 310830 | 0.53 | |

| 876 | 876.5 | 310785 | 0.20 | 896 | 896.5 | 310831 | 0.21 | |

| 876.5 | 877 | 310786 | 0.28 | 896.5 | 897 | 310832 | 0.03 | |

| 877 | 877.5 | 310787 | 1.27 | 897 | 897.5 | 310833 | 0.01 | |

| 877.5 | 878 | 310788 | 0.36 | 897.5 | 898 | 310834 | 0.02 | |

| 878 | 878.5 | 310789 | 0.64 | 898 | 898.5 | 310836 | 0.01 | |

| 878.5 | 879 | 310790 | 0.29 | 898.5 | 899 | 310837 | 0.01 | |

| 879 | 879.5 | 310792 | 41.60 | 899 | 899.5 | 310838 | 0.01 | |

| 879.5 | 880 | 310793 | 2.47 | 899.5 | 900 | 310839 | 0.00 |

Photo 1: TAN18-DD228 Visible gold at 865.5m 155 g/t Au

Photo 2: TAN18-DD228 Visible gold at 868.5m 188 g/t Au

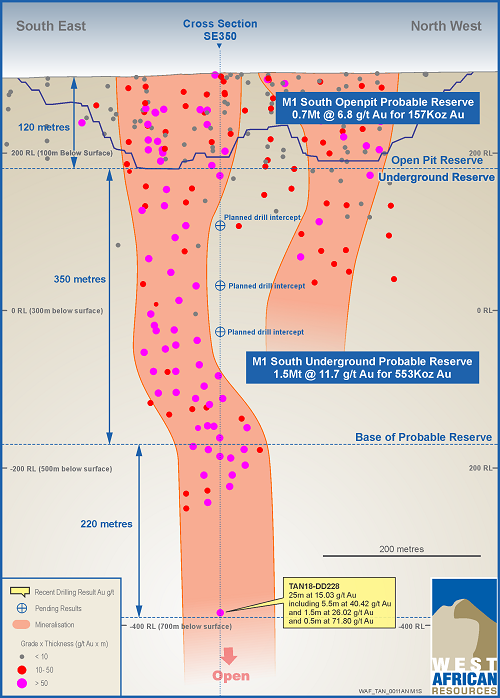

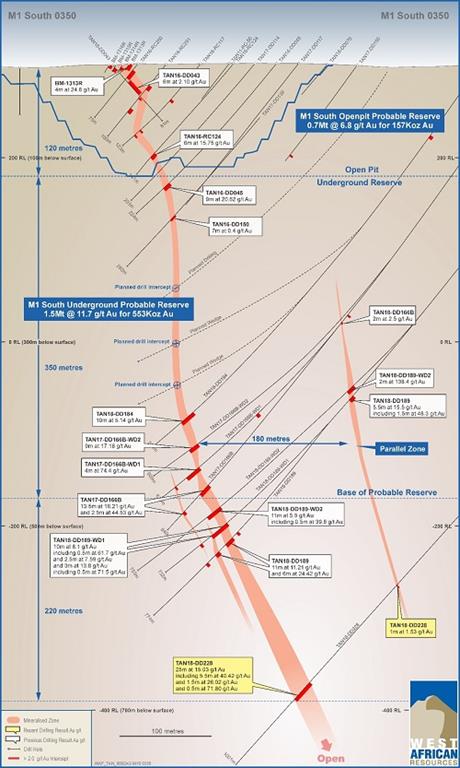

A long-section through the M1 South deposit (Figure 1) shows the mid-point of the high grade gold intercept in TAN18-DD228 at approximately 700m vertical below surface. The June Feasibility Study (FS) (ASX/TSXV: 22/6/18) proposed open-pit mining will occur down to 120m vertical and underground mining will be occur from 120m below surface to approximately 470m below surface over 4.5 years. Drilling completed since June 2018 has continued to intercept high grade mineralisation which has been extended more than 220m beneath underground reserves, with significant results including:

- TAN18-DD196: 8m at 7.0 g/t from 693 including 1.5m at 21.6 g/t Au

- TAN18-DD189: 11m at 11.2 g/t from 654 and 6m at 24.4 g/t Au from 675m

- TAN18-DD214A: 0.5m at 520 g/t Au from 578m

- TAN18-DD214A: 23m at 7.3 g/t Au from 617m including 4m at 24.4 g/t Au

- TAN18-DD189-WD1: 10m at 8.1 g/t Au from 646.5m, including 0.5m at 61.7 g/t Au

- TAN18-DD196-WD2: 10.5m at 8.8 g/t Au from 648m, including 0.5m at 138 g/t Au

- TAN18-DD214A-WD1: 21.5m at 15.3 g/t Au from 614m, including 0.5m at 115 g/t Au

- TAN18-DD214A-WD2: 14.5m at 19.9 g/t Au from 595.5m, including 1m at 219 g/t Au

- TAN18-DD228: 25m at 15 g/t Au from 862m including 5.5m at 40.4 g/t, 1.5m at 26.02 g/t Au from 879m and 0.5m at 71.80 g/t Au from 886m

Mineralisation intercepted in TAN18-DD228 has the potential to extend the underground mine schedule past 7.5 years, assuming the vertical advance of underground mining remains consistent with upper levels and that further infill drilling is successful.

The Company will deliver a further FS update by the end of Q1 2019 incorporating updated resources and reserves, and an improved mine schedule based on higher plant throughput (ASX/TSXV: 8/11/2018). A significant improvement in project economics versus the June 2018 FS is expected by delivering more gold in the early years of the operation from an accelerated mine schedule with a relatively small change in the overall project capital requirements.

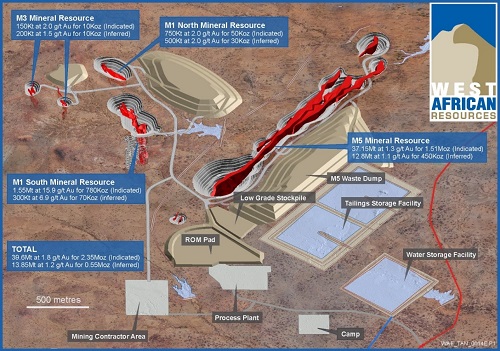

A summary long-section and cross-section through M1 South are presented as Figures 1 and 2, along with a location plan as Figure 3. Photos 1 - 2 show visible gold intercepted in TAN18-DD228. A summary of significant intercepts is presented in Table 1 (2 g/t Au Cut Off) and Table 2 (30 g/t Au Cut Off) for 2018 drilling.

About West African Resources

West African Resources Limited (ASX, TSXV: WAF) recently announced the results of its updated Feasibility Study for the Sanbrado Gold Project in Burkina Faso. The study envisages an initial 11-year mine life, including 4.5 years of underground mining, and showed a 76% increase in Probable Reserves to 1.6 million ounces (20.4Mt at 2.4g/t gold). The project will have average annual production over the first 5 years of mine life of 211,000 ounces gold and a 16 month post-tax pay back on US$185 million pre-production capital costs. Project economics are robust, with AISC of US$551/oz over first 5 years and US$640 over life of mine. The project returns a pre-tax NPV5% of US$567m (A$754m) and pre-tax IRR of 62%, and Post-tax NPV5% of US$405m (A$540m) and post-tax IRR of 49%. Mineralisation is open at depth and along strike and therefore value add drilling on the project is ongoing, with further resource and reserve updates expected later in Q1 2019.

Figure 1: M1 South Long-section

Figure 2: M1 South Cross-section SE0350

Figure 3: Sanbrado Gold Project Layout

Table 1

M1 South Deposit

Significant Intercepts 2 g/t Cut Off

| Hole ID | From | To | Interval | Au g/t | Dip | Azi | EOH | Easting | Northing | RL | Section | Prospect |

| TAN18-DD184 | 496.5 | 506.5 | 10 | 5.14 | -55 | 230 | 544 | 741801 | 1337220 | 300 | SE0375 | M1 S |

| TAN18-DD187 | 378 | 378.5 | 0.5 | 2.64 | -55 | 230 | 450 | 741748 | 1337138 | 297 | SE0400 | M1 S |

| TAN18-DD187 | 389.5 | 391.5 | 2 | 3.28 |

|

|

|

|

|

|

|

|

| TAN18-DD187 | 394.5 | 395 | 0.5 | 2.38 |

|

|

|

|

|

|

|

|

| TAN18-DD189 | 654 | 665 | 11 | 11.21 | -57 | 230 | 774 | 741899 | 1337313 | 301 | SE0375 | M1 S |

| TAN18-DD189 | 675 | 681 | 6 | 24.42 |

|

|

|

|

|

|

|

|

| TAN18-DD189 | 695 | 695.5 | 0.5 | 19.90 |

|

|

|

|

|

|

|

|

| TAN18-DD196 | 676 | 676.5 | 0.5 | 17.90 | -60 | 230 | 757 | 741916 | 1337294 | 301 | SE0400 | M1 S |

| TAN18-DD196 | 683.5 | 684 | 0.5 | 8.63 |

|

|

|

|

|

|

|

|

| TAN18-DD196 | 693 | 710 | 17 | 4.07 |

|

|

|

|

|

|

|

|

| TAN18-DD206 | 126 | 134 | 8 | 12.89 | -52 | 225 | 183 | 741640 | 1336992 | 301 | SE0425 | M1 S |

| TAN18-DD206 | 142.5 | 157 | 14.5 | 27.93 |

|

|

|

|

|

|

|

|

| TAN18-DD206 | 170.5 | 172 | 1.5 | 22.10 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 423 | 423.5 | 0.5 | 2.40 | -55 | 230 | 555 | 741834 | 1337121 | 298 | SE0475 | M1 S |

| TAN18-DD209 | 425.5 | 426 | 0.5 | 2.64 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 440.5 | 444.5 | 4 | 25.72 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 456 | 456.5 | 0.5 | 2.04 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 482 | 496 | 14 | 7.82 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 578 | 578.5 | 0.5 | 520.00 | -62 | 230 | 766 | 741881 | 1337330 | 301 | SE0350 | M1 S |

| TAN18-DD214A | 617 | 640 | 23 | 7.33 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 674 | 674.5 | 0.5 | 2.40 |

|

|

|

|

|

|

|

|

| TAN18-DD217A | 603.5 | 610 | 6.5 | 6.83 | -60 | 230 | 702 | 741862 | 1337345 | 302 | SE0325 | M1 S |

| TAN18-DD216 | 681.5 | 683.5 | 2 | 5.13 | -60 | 230 | 783 | 741930 | 1337278 | 301 | SE0425 | M1 S |

| TAN18-DD216 | 689.5 | 690 | 0.5 | 2.47 |

|

|

|

|

|

|

|

|

| TAN18-DD216 | 705.5 | 714.5 | 9 | 3.02 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD1 | 646.5 | 656.5 | 10 | 8.14 | -57 | 230 | 732 | 741899 | 1337313 | 301 | SE0375 | M1 S |

| TAN18-DD189-WD1 | 666 | 668.5 | 2.5 | 7.59 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD1 | 682 | 685 | 3 | 13.82 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD2 | 449 | 451 | 2 | 138.4 | -57 | 230 | 753 | 741899 | 1337313 | 301 | SE0375 | M1 S |

| TAN18-DD189-WD2 | 639 | 650 | 11 | 5.94 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD2 | 656 | 657.5 | 1.5 | 2.81 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD2 | 675.5 | 676 | 0.5 | 33.7 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD1 | 656.5 | 668.5 | 12 | 3.4 | -60 | 230 | 748 | 741916 | 1337294 | 301 | SE0400 | M1 S |

| TAN18-DD196-WD1 | 684 | 684.5 | 0.5 | 2.61 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD1 | 690 | 690.5 | 0.5 | 192 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD2 | 637 | 638 | 1 | 18.08 | -60 | 230 | 703 | 741916 | 1337294 | 301 | SE0400 | M1 S |

| TAN18-DD196-WD2 | 646 | 646.5 | 0.5 | 3.81 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD2 | 648 | 658.5 | 10.5 | 8.83 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD2 | 667.5 | 668.5 | 1 | 36.85 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 584 | 584.5 | 0.5 | 2.34 | -62 | 230 | 703 | 741881 | 1337330 | 301 | SE0350 | M1 S |

| TAN18-DD214A-WD1 | 586.5 | 587 | 0.5 | 3.85 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 614 | 635.5 | 21.5 | 15.31 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD2 | 595.5 | 610 | 14.5 | 19.88 | -62 | 230 | 697 | 741881 | 1337330 | 301 | SE0350 | M1 S |

| TAN18-DD228 | 862 | 887 | 25 | 15.03 | -55 | 230 | 1000.8 | 742050 | 1337471 | 301.5 | SE0350 | M1 S |

Table 2

M1 South Deposit

Significant Intercepts 30 g/t Cut Off

| Hole ID | From | To | Interval | Au g/t | Dip | Azi | EOH | Easting | Northing | RL | Section | Prospect |

| TAN18-DD184 | 505.5 | 506 | 0.5 | 33.9 | -55 | 230 | 544 | 741801 | 1337220 |

| SE0375 | M1S |

| TAN18-DD189 | 455.5 | 457 | 1.5 | 48.31 | -57 | 230 | 774 | 741899 | 1337313 |

| SE0375 | M1S |

| TAN18-DD189 | 655 | 656 | 1 | 39.8 |

|

|

|

|

|

|

|

|

| TAN18-DD189 | 680.5 | 681 | 0.5 | 240 |

|

|

|

|

|

|

|

|

| TAN18-DD196 | 693.5 | 694 | 0.5 | 37.9 | -60 | 230 | 757 | 741916 | 1337294 |

| SE0400 | M1S |

| TAN18-DD206 | 132 | 132.5 | 0.5 | 183 | -52 | 225 | 183 | 741640 | 1336992 |

| SE0425 | M1S |

| TAN18-DD206 | 142.5 | 145.5 | 3 | 64.86 |

|

|

|

|

|

|

|

|

| TAN18-DD206 | 151 | 154.5 | 3.5 | 52.8 |

|

|

|

|

|

|

|

|

| TAN18-DD206 | 171 | 171.5 | 0.5 | 61.5 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 441 | 443.5 | 2.5 | 38.21 | -55 | 230 | 555 | 741834 | 1337121 |

| SE0475 | M1S |

| TAN18-DD209 | 482 | 482.5 | 0.5 | 55.8 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 487.5 | 488 | 0.5 | 57.9 |

|

|

|

|

|

|

|

|

| TAN18-DD209 | 495.5 | 496 | 0.5 | 37.9 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 578 | 578.5 | 0.5 | 520 | -62 | 230 | 766 | 741881 | 1337330 |

| SE0350 | M1S |

| TAN18-DD214A | 618.5 | 619 | 0.5 | 79.6 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 624 | 624.5 | 0.5 | 33.9 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 625 | 625.5 | 0.5 | 41.8 |

|

|

|

|

|

|

|

|

| TAN18-DD214A | 639 | 639.5 | 0.5 | 36 |

|

|

|

|

|

|

|

|

| TAN18-DD216 | 705.5 | 706 | 0.5 | 37.8 | -60 | 230 | 783 | 741930 | 1337278 |

| SE0425 | M1S |

| TAN18-DD217A | 609.5 | 610 | 0.5 | 35.7 | -60 | 230 | 702 | 741862 | 1337345 |

| SE0325 | M1S |

| TAN18-DD189-WD1 | 651.5 | 652 | 0.5 | 33.8 | -57 | 230 | 732 | 741899 | 1337313 |

| SE0375 | M1S |

| TAN18-DD189-WD1 | 653.5 | 654 | 0.5 | 61.7 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD1 | 684.5 | 685 | 0.5 | 71.5 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD2 | 449 | 451 | 2 | 138.4 | -57 | 230 | 753 | 741899 | 1337313 |

| SE0375 | M1S |

| TAN18-DD189-WD2 | 639 | 639.5 | 0.5 | 39.8 |

|

|

|

|

|

|

|

|

| TAN18-DD189-WD2 | 675.5 | 676 | 0.5 | 33.7 |

|

|

|

|

|

|

|

|

| TAN18-DD196-WD1 | 690 | 690.5 | 0.5 | 192 | -60 | 230 | 748 | 741916 | 1337294 |

| SE0400 | M1S |

| TAN18-DD196-WD2 | 657 | 657.5 | 0.5 | 138 | -60 | 230 | 703 | 741916 | 1337294 |

| SE0400 | M1S |

| TAN18-DD196-WD2 | 667.5 | 668.5 | 1 | 36.85 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 616 | 616.5 | 0.5 | 102 | -62 | 230 | 703 | 741881 | 1337330 |

| SE0350 | M1S |

| TAN18-DD214A-WD1 | 620.5 | 621 | 0.5 | 115 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 624 | 624.5 | 0.5 | 42 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 630.5 | 631 | 0.5 | 87.9 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD1 | 634.5 | 635 | 0.5 | 39.7 |

|

|

|

|

|

|

|

|

| TAN18-DD214A-WD2 | 600.5 | 601.5 | 1 | 219 | -62 | 230 | 697 | 741881 | 1337330 |

| SE0350 | M1S |

| TAN18-DD214A-WD2 | 608 | 609 | 1 | 46.85 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 863.5 | 864 | 0.5 | 31.8 | -55 | 230 | 1000.8 | 742050 | 1337471 | 301.5 | SE0350 | M1 S |

| TAN18-DD228 | 865 | 865.5 | 0.5 | 155 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 868 | 868.5 | 0.5 | 188 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 868.5 | 869 | 0.5 | 35.9 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 879 | 879.5 | 0.5 | 41.6 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 880 | 880.5 | 0.5 | 34 |

|

|

|

|

|

|

|

|

| TAN18-DD228 | 886 | 886.5 | 0.5 | 71.8 |

|

|

|

|

|

|

|

|

- * denotes ending in mineralisation

- All holes are diamond holes.

- All reported intersections from the current 2018 program are assayed at 1m intervals for M5 and 0.5m for M1 where possible.

- Sample preparation and Fire Assay conducted by SGS Ouagadougou. Assayed by 50g fire assay with AAS finish. All samples >5 g/t Au are checked by 50g fire assay with gravimetric finish.

- Mineralised intervals for DD reported >2g/t Au with a maximum of 5 m of internal dilution of less than 2/t gold. No top cut applied.

- QA/QC protocol: we insert one blank, one standard and one duplicate for every 17 samples (3 QA/QC within every 20 samples).

| Table 3: Sanbrado Gold Project | ||||||||

| Resource | Category | Cutoff | Indicated Resource | Inferred Resource | ||||

| Tonnes | Grade | Au Oz | Tonnes | Grade | Au Oz | |||

| M1 South | O/P <120m | 0.5 | 800,000 | 6.6 | 170,000 | 50,000 | 4.8 | 10,000 |

| U/G >120m | 3.0 | 750,000 | 25.5 | 620,000 | 250,000 | 7.6 | 60,000 | |

| Total | Combined | 1,550,000 | 15.9 | 780,000 | 300,000 | 6.9 | 70,000 | |

| M5 | O/P | 0.5 | 37,150,000 | 1.3 | 1,510,000 | 12,800,000 | 1.1 | 450,000 |

| M1 North | O/P | 0.5 | 750,000 | 2.0 | 50,000 | 500,000 | 2.0 | 30,000 |

| M3 | O/P | 0.5 | 150,000 | 2.0 | 10,000 | 200,000 | 1.5 | 10,000 |

| Total | Combined | 39,600,000 | 1.8 | 2,350,000 | 13,850,000 | 1.2 | 550,000 | |

| Table 4: Sanbrado Gold Project | ||||

| Deposit | Strip Ratio | (Mt) | Au Grade | Cont. Au |

| M5 Open Pit | 3.8 | 17.5 | 1.5 | 817 |

| M1Sth Open Pit | 22.6 | 0.7 | 6.8 | 157 |

| M1Nth Open Pit | 8.4 | 0.6 | 2.1 | 39 |

| M3 Open Pit | 6.1 | 0.1 | 1.8 | 8 |

| Sub Total Open Pit | 4.6 | 18.9 | 1.7 | 1,021 |

| M1Sth Underground | - | 1.5 | 11.7 | 553 |

| Total | 20.4 | 2.4 | 1,574 | |

- Note: Due to rounding, numbers presented throughout this document may not add up precisely to the totals provided and percentages may not precisely reflect the absolute figures.

- Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as downhole gamma sondes, or handheld XRF instruments, etc.). These examples should not be taken as limiting the broad meaning of sampling.

- Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

- Aspects of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard’ work has been done this would be relatively simple (e.g. ‘reverse circulation drilling was used to obtain 1m samples from which 3kg was pulverised to produce a 30g charge for fire assay’). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information.

- The area of the Mankarga 5 resource was drilled using Reverse Circulation (RC), Aircore (AC) and Diamond drillholes (DD) on a nominal 50m x 25m grid spacing. A total of 760 AC holes (24,062m), 118 DC holes (26,588m), and 95 RC holes (10,373m) were drilled by WAF between 2013 and 2018. A total of 60 RC holes (7,296m) and 71 DD holes (15,440m) were drilled by Channel Resources (CHU) in 2010-2012. Holes were angled towards 120° or 300° magnetic at declinations of between -50° and -60°, to optimally intersect the mineralised zones.

- The area of the Mankarga 1 resource was drilled using Reverse Circulation (RC), Aircore (AC) and Diamond drillholes (DD) on a nominal 25m x 20m grid spacing. A total of 397 AC holes (7,480m), 122 DC and DT holes (29,870m) and 216 RC holes (23,338m) were drilled by WAF between 2015 and 2017. A total of 23 RC holes (3,060m) and 7 DD holes (1,199m) were drilled by Channel Resources (CHU) in 2010-2012. Holes were angled towards 020°, 045°, 180°or 225° magnetic at declinations of between -50° and -60°, to optimally intersect the mineralised zones.

- The area of the Mankarga 3 resource was drilled using Aircore (AC), RC drilling (RC) and Diamond drillholes (DD) on a nominal 20m x 20m grid spacing. A total of 269 AC holes (9,008m), 4 DD holes (384.m), and 9 RC holes (962m) were drilled by West African Resources (WAF) in 2015-2016. Holes were angled towards 090° or 225° magnetic at declinations of -50°, to optimally intersect the mineralised zones.

- All RC samples were weighed to determine recoveries. WAF and CHU RC samples were split and sampled at 1m and 2m intervals respectively using a three-tier riffle splitter. Diamond core is a combination of HQ, NQ2 and NQ3 sizes and all Diamond core was logged for lithological, alteration, geotechnical, density and other attributes. In addition, WAF Diamond core was logged for structural attributes. Half-core sampling was completed at 1m and 1.5m intervals for WAF and CHU respectively. QAQC procedures were completed as per industry standard practices (i.e., certified standards, blanks and duplicate sampling were sent with laboratory sample dispatches).

- CHU RC samples were dispatched to Abilab Burkina SARL (ALS Laboratory Group) in Ouagadougou. CHU DD samples were dispatched to SGS Burkina Faso SA (SGS) in Ouagadougou and WAF RC and DD samples were dispatched to BIGS Global Burkina SARL (BIGS) in Ouagadougou until July 2017. As a result of slow turnaround, samples from the WAF drilling programmes were collected and submitted to SGS since July 2017. Up to the 25th April 2018, a total of 235 AC samples, 4,184 RC samples, and 26,002 DC samples (all excluding QAQC samples) have been submitted to SGS. The Diamond core samples were crushed, dried and pulverised (total prep) to produce a sub sample for analysis for gold by 50g standard fire assay method (FA) followed by an atomic absorption spectrometry (AAS) finish. WAF and CHU RC drilling was used to obtain 1m and 2m composite samples respectively from which 3kg was pulverised (total prep) to produce a sub sample for assaying as above.

- Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc.).

- Diamond drilling in the resource area comprises NQ2, NQ3 or HQ sized core. RC depths range from 13m to 204m and DD depths range from 49.5m to 667m. WAF Diamond core was oriented using a combination of orientation spear with >50% of orientations rated as ''confident'', Reflex ACT II system and Coretell© ORIshot orientation system. RC and AC drilling within the resource area comprises 5.5 inch and 4.5 inch diameter face sampling hammer and aircore blade drilling.

- Method of recording and assessing core and chip sample recoveries and results assessed.

- Measures taken to maximise sample recovery and ensure representative nature of the samples.

- Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material.

- Diamond core and RC recoveries are logged and recorded in the database. Overall recoveries are >90% for the diamond core and >70% for the RC; there are no core loss issues or significant sample recovery problems. A technician is always present at the rig to monitor and record recovery.

- Diamond core is reconstructed into continuous runs on an angle iron cradle for orientation marking. Depths are checked against the depth given on the core blocks and rod counts are routinely carried out by the drillers. RC samples were visually checked for recovery, moisture and contamination.

- The resource is defined by DD and RC drilling, which have high sample recoveries. No relationship between sample recovery and grade have been identified at the project. The consistency of the mineralised intervals and density of drilling is considered to preclude any issue of sample bias due to material loss or gain.

- Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

- Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc.) photography.

- The total length and percentage of the relevant intersections logged.

- Geotechnical logging was carried out on all diamond drillholes for recovery, RQD and number of defects (per interval). Information on structure type, dip, dip direction, alpha angle, beta angle, texture, shape, roughness and fill material is stored in the structure/geotechnical table of the database.

- Logging of diamond core and RC samples recorded lithology, mineralogy, mineralisation, structural (WAF DD only), weathering, alteration, colour and other features of the samples. Core was photographed in both dry and wet form.

- All drilling has been logged to standard that is appropriate for the category of Resource which is being reported.

- If core, whether cut or sawn and whether quarter, half or all core taken.

- If non-core, whether riffled, tube sampled, rotary split, etc. and whether sampled wet or dry.

- For all sample types, the nature, quality and appropriateness of the sample preparation technique.

- Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

- Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling.

- Whether sample sizes are appropriate to the grain size of the material being sampled.

- Core was cut in half onsite using a CM core cutter. All samples were collected from the same side of the core.

- RC samples were collected on the rig using a three tier splitter. All samples were dry.

- The sample preparation for all samples follows industry standard practice. The samples were dispatched to the laboratory (as per section ‘Sampling Techniques’) where they were crushed, dried and pulverised to produce a sub sample for analysis. Sample preparation involved oven drying, coarse crushing, followed by total pulverisation LM2 grinding mills to a grind size of 90% passing 75 microns.

- Field QC procedures involve the use of certified reference material as assay standards, blanks and duplicates. The insertion rate of these averaged 3:20.

- Field duplicates were taken on 1m and 2m composites for WAF and CHU RC samples respectively, using a riffle splitter.

- The sample sizes are considered to be appropriate to correctly represent the style of mineralisation, the thickness and consistency of the intersections.

- The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

- For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

- Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established.

- The laboratory used an aqua regia digest followed by fire assay with an AAS finish for gold analysis.

- No geophysical tools were used to determine any element concentrations used in this Resource Estimate.

- Sample preparation checks for fineness were carried out by the laboratory as part of their internal procedures to ensure the grind size of 90% passing 75 micron was being attained. Laboratory QAQC involves the use of internal lab standards using certified reference material, blanks, splits and duplicates as part of the in house procedures. Certified reference materials, having a good range of values, were inserted blindly and randomly. Results highlight that sample assay values are accurate and that contamination has been contained.

- Repeat or duplicate analysis for samples reveals that precision of samples is within acceptable limits. For Diamond core, one blank and one standard is inserted every 18 core samples and no duplicates. For RC samples, one blank, one standard and one duplicate is inserted every 17 samples.

- The verification of significant intersections by either independent or alternative company personnel.

- The use of twinned holes.

- Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

- Discuss any adjustment to assay data.

- The CP has visually verified significant intersections in diamond core and RC drilling as part of the Resource Estimation process.

- Six RC holes and one diamond hole were twinned by diamond holes (2 drilled by WAF, 5 by CHU) for the Mankarga 5 prospect. Four RC holes were twinned by RC holes and two further RC holes were twinned by diamond holes (all drilled by WAF) at the Mankarga 1 prospect. Results returned from the twins were consistent with original holes.

- Primary data was collected using a set of company standard Excel™ templates on Toughbook™ laptop computers using lookup codes. The information was validated on-site by the Company’s database technicians and then merged and validated into a final AccessTM database by the company’s database manager.

- The results confirmed the initial intersection geology.

- No adjustments or calibrations were made to any assay data used in this estimate.

- Accuracy and quality of surveys used to locate drillholes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

- Specification of the grid system used.

- Quality and adequacy of topographic control.

- All drillholes have been located by DGPS in UTM grid WGS84 Z30N. WAF DD downhole surveys were completed at least every 24m and at the end of hole using a Reflex downhole survey tool. CHU DD downhole surveys were completed every 3m with a Reflex EZ-Trac survey tool and CHU RC holes were surveyed every 5m using a GYRO Smart survey instrument.

- The grid UTM Zone 30 WGS 84 was used. A local grid orientated parallel to the strike of Mankarga (bearing 030 UTM) has recently been implemented and will be used for future work

- Ground DGPS, Real time topographical survey and a drone survey was used for topographic control.

- Data spacing for reporting of Exploration Results.

- Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

- Whether sample compositing has been applied.

- The nominal drillhole spacing is 50m (northeast) by 20m (northwest) for the Mankarga 5 prospect, 25m (northwest) by 20m (northeast) for the Mankarga 1 prospect.

- The mineralised domains have demonstrated sufficient continuity in both geology and grade to support the definition of Inferred and Indicated Mineral Resources as per the guidelines of the 2012 JORC Code.

- Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

- If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have intrduced a sampling bias, this should be assessed and reported if material.

- The majority of the data is drilled to either magnetic 120° or 300° orientations for Mankarga 5 and magnetic 045° or 225° orientations for Mankarga 1 and Mankarga3, which is orthogonal/perpendicular to the orientation of the mineralised trend. The bulk of the drilling is almost perpendicular to the mineralised domains. Structural logging based on oriented core indicates that the main mineralisation controls are largely perpendicular to drill direction.

- No orientation based sampling bias has been identified in the data at this point.

- The measures taken to ensure sample security.

- Chain of custody is managed by WAF. Samples are stored on site and delivered by WAF personnel to BIGS Ouagadougou for sample preparation. Whilst in storage, they are kept under guard in a locked yard. Tracking sheets are used to track the progress of batches of samples.

- The results of any audits or reviews of sampling techniques and data.

- WAF personnel completed site visits and data review during the due diligence period prior to acquiring Channel Resources Ltd. No material issues were highlighted. During 2012 AMEC completed a site visit and data review as part of the NI43-101 report dated 29 July 2012. No material issues were noted. between May 2014 and May 2017 the CP has completed several site visits and data review as part of this Resource Estimate.

- Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

- The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area.

- The original Tanlouka Permit covered 115km². The Company owned 100% of the Tanlouka Permis de Recherche arrêté No 2013 000128/MCE/SG/DGMG, which covered 115km² and was valid until 27 January 2016. In October 2015, the Company applied for the Sanbrado Mining license which covers the south eastern corner of the Tanlouka permit over a 26km² area. The Sanbrado Mining Permit application was passed by the Council of Ministers in January 2017. Furthermore, the Company also applied for the Manesse permis de recherche which covers the residual area of the expired Tanlouka permit; this permit was granted in January 2017 (Arrêté No 17/014/MEMC/SG/DGCMIM). The Sanbrado Mining Permit was issued by ministerial decree in March 2017 No 2017 – 104/PRES/PM/MEMC/MINEFID/MEEVCC

- All licences, permits and claims are granted for gold. All fees have been paid, and the permits are valid and up to date with the Burkinabe authorities. The payment of gross production royalties is provided for by the Mining Code and the amount of royalty to be paid is 3% up to $1000/oz, 4% up to $1300/oz and >$1300/oz 5%

- Acknowledgment and appraisal of exploration by other parties.

- Exploration activities on the original Tanlouka permit by previous workers have included geological mapping, rock and chip sampling, geophysical surveys, geochemical sampling and drilling, both reverse circulation and core. This work was undertaken by Channel Resources personnel and their consultants from 1994 until 2012.

- Deposit type, geological setting and style of mineralisation.

- The project is located within a strongly arcuate volcano-sedimentary northeast-trending belt that is bounded to the east by the Tiébélé-Dori-Markoye Fault, one of the two major structures subdividing Burkina Faso into three litho-tectonic domains. The geology of the Tanlouka area is characterised by metasedimentary and volcanosedimenatry rocks, intruded by mafic, diorite and granodiorite intrusions. The Mankarga prospect area is characterised by a sedimentary pile which is mostly composed of undifferentiated pelitic and psammitic metasediments as well as volcanosedimentary units. This pile has been intruded by a variably porphyritic granodiorite, overprinted by shearing and mylonites in places, and is generally parallel to sub-parallel with the main shear orientation. In a more regional context, the sedimentary pile appears ''wedged'' between regional granites and granodiorites. The alteration mineralogy varies from chloritic to siliceous, albitic, calcitic and sericite-muscovite. Gold mineralisation in the project area is mesothermal orogenic in origin and structurally controlled. The project area is interpreted to host shear zone type quartz-vein gold mineralisation. Observed gold mineralisation at the Mankarga prospects appears associated with quartz vein and veinlet arrays, silica, sulphide and carbonate-albite, tourmaline-biotite alteration. Gold is free and is mainly associated with pyrrhotite, pyrite, minor chalcopyrite and arsenopyrite disseminations and stringers.

- A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drillholes:

- easting and northing of the drillhole collar

- elevation or RL (Reduced Level - elevation above sea level in metres) of the drillhole collar

- dip and azimuth of the hole

- downhole length and interception depth

- hole length.

- If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

- Significant intercepts that form the basis of this Resource Estimate have been released to the ASX in previous announcements (available on the WAF website) with appropriate tables incorporating Hole ID, Easting, Northing, Dip, Azimuth, Depth and Assay Data. Appropriate maps and plans also accompany this Resource Estimate announcement.

- Drilling completed by Channel Resources is documented in the publically available report "NI 43-101 Technical Report on Mineral Resources for the Mankarga 5 Gold Deposit Tanlouka Property, Burkina Faso for Channel Resources Ltd" prepared by AMEC Consultants and dated 17 August 2012.

- A complete listing of all drillhole details is not necessary for this report which describes the Mankarga5 and Mankarga 1 Gold Resource and in the Competent Person's opinion the exclusion of this data does not detract from the understanding of this report.

- In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cutoff grades are usually Material and should be stated.

- Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

- The assumptions used for any reporting of metal equivalent values should be clearly stated.

- All intersections are assayed on one meter intervals. No top cuts have been applied to exploration results. Mineralised intervals are reported with a maximum of 2m of internal dilution of less than 0.5g/t Au. Mineralised intervals are reported on a weighted average basis.

- These relationships are particularly important in the reporting of Exploration Results.

- If the geometry of the mineralisation with respect to the drillhole angle is known, its nature should be reported.

- If it is not known and only the downhole lengths are reported, there should be a clear statement to this effect (e.g. 'downhole length, true width not known').

- The orientation of the mineralised zone has been established and the majority of the drilling was planned in such a way as to intersect mineralisation in a perpendicular manner or as close as practicable. Topographic limitations were evident for some holes and these were drilled from less than ideal orientations. However, where possible, earthworks were carried out in order to accomplish drill along optimum orientations.

- Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drillhole collar locations and appropriate sectional views.

- The appropriate plans and sections have been included in the body of this document.

- Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

- All grades, high and low, are reported accurately with ''from'' and ''to'' depths and ''hole identification'' shown.

- Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

- Detailed metallurgical test work has been carryout as part of the FS. Test work shows that the ore is amenable to conventional crushing, grinding and CIL processing. LOM recoveries have been determined to be 90.7%

- The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step-out drilling).

- Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

- A program of dedicated metallurgical and geotechnical drillholes has been completed. Some grade control pattern test work is planned prior to commencing mining.

Competent Persons and Qualified Persons Statement

Information in this announcement that relates to exploration results, exploration targets or mineral resources is based on information compiled by Mr Richard Hyde, a Director, who is a Member of The Australian Institute of Mining and Metallurgy and Australian Institute of Geoscientists. Mr Hyde has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (the JORC Code) and a Qualified Person under National Instrument 43-101. Mr Hyde consents to the inclusion in this announcement of the statements based on his information in the form and context in which they appear.

Forward Looking Information

This news release contains ''forward-looking information'' within the meaning of applicable Canadian and Australian securities legislation, including information relating to West African's future financial or operating performance may be deemed ''forward looking''. All statements in this news release, other than statements of historical fact, that address events or developments that West African expects to occur, are ''forward-looking statements''. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words ''expects'', ''does not expect'', ''plans'', ''anticipates'', ''does not anticipate'', ''believes'', ''intends'', ''estimates'', ''projects'', ''potential'', ''scheduled'', ''forecast'', ''budget'' and similar expressions, or that events or conditions ''will'', ''would'', ''may'', ''could'', ''should'' or ''might'' occur. All such forward-looking statements are based on the opinions and estimates of the relevant management as of the date such statements are made and are subject to important risk factors and uncertainties, many of which are beyond West African’s ability to control or predict. Forward-looking statements are necessarily based on estimates and assumptions that are inherently subject to known and unknown risks, uncertainties and other factors that may cause actual results, level of activity, performance or achievements to be materially different from those expressed or implied by such forward-looking statements. In the case of West African, these facts include their anticipated operations in future periods, planned exploration and development of its properties, and plans related to its business and other matters that may occur in the future. This information relates to analyses and other information that is based on expectations of future performance and planned work programs. Statements concerning mineral resource estimates may also be deemed to constitute forward-looking information to the extent that they involve estimates of the mineralization that will be encountered if a mineral property is developed.

Forward-looking information is subject to a variety of known and unknown risks, uncertainties and other factors which could cause actual events or results to differ from those expressed or implied by the forward-looking information, including, without limitation: exploration hazards and risks; risks related to exploration and development of natural resource properties; uncertainty in West African’s ability to obtain funding; gold price fluctuations; recent market events and conditions; risks related to the uncertainty of mineral resource calculations and the inclusion of inferred mineral resources in economic estimation; risks related to governmental regulations; risks related to obtaining necessary licenses and permits; risks related to their business being subject to environmental laws and regulations; risks related to their mineral properties being subject to prior unregistered agreements, transfers, or claims and other defects in title; risks relating to competition from larger companies with greater financial and technical resources; risks relating to the inability to meet financial obligations under agreements to which they are a party; ability to recruit and retain qualified personnel; and risks related to their directors and officers becoming associated with other natural resource companies which may give rise to conflicts of interests. This list is not exhaustive of the factors that may affect West African’s forward-looking information. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in the forward-looking information.

West African’s forward-looking information is based on the reasonable beliefs, expectations and opinions of their respective management on the date the statements are made, and West African does not assume any obligation to update forward looking information if circumstances or management’s beliefs, expectations or opinions change, except as required by law. For the reasons set forth above, investors should not place undue reliance on forward-looking information. For a complete discussion with respect to West African, please refer to West African’s financial statements and related MD&A, all of which are filed on SEDAR at www.sedar.com.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

JORC Table 1, Sections 1-2

Section 1 Sampling Techniques and Data

| Criteria | JORC Code Explanation | Commentary |

|

|

|

|

| Sampling Techniques | | |

| Drilling Techniques | | |

| Drill Sample Recovery | | |

| Logging | | |

| Sub-Sampling Techniques and Sample Preparation | | |

| Quality of Assay Data and Laboratory Tests | | |

| Verification of Sampling and Assaying | | |

| Location of Data Points | | |

| Data Spacing and Distribution | | |

| Orientation of Data in Relation to Geological Structure | | |

| Sample Security | | |

| Audits or Reviews | | |

Section 2 Reporting of Exploration Results

| Criteria | JORC Code Explanation | Commentary |

| Mineral Tenement and Land Tenure Status | | |

| Exploration Done by Other Parties | | |

| Geology | | |

| Drillhole Information | | |

| Data Aggregation Methods | | |

| Relationship Between Mineralisation Widths and Intercept Lengths | | |

| Diagrams | | |

| Balanced Reporting | | |

| Other Substantive Exploration Data | | |

| Further Work | | |

SOURCE: West African Resources Ltd