Westhaven Reports 95% Gold and 96% Silver Recoveries in Preliminary Metallurgical Test Work at the Shovelnose Gold Property

VANCOUVER, British Columbia, Nov. 15, 2021 (GLOBE NEWSWIRE) -- Westhaven Gold Corp. (TSX-V:WHN) is pleased to announce preliminary metallurgical test results at its 100% owned 17,623-hectare Shovelnose gold property. Shovelnose is located within the prospective Spences Bridge Gold Belt (SBGB), which borders the Coquihalla Highway 30 kilometers south of Merritt, British Columbia.

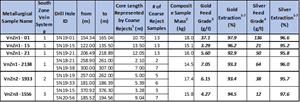

Gareth Thomas, President & CEO of Westhaven Gold, states: “We are pleased that two tranches of initial metallurgical test work undertaken by ALS Metallurgy Kamloops demonstrate high gold (average 95%) and silver (average 96%) recoveries from three quartz vein systems that comprise the South Zone. Mineralization is non-refractory and amenable to recovery by a standard industry process flowsheet. Results will support our maiden resource estimate on the South Zone, due in early Q1 2022.”

Highlights of Work by ALS Metallurgy Kamloops:

- representative samples (14.5 to 18.0 kg mass) were submitted from each of the three main quartz vein systems within the South Zone (four from Vein Zone 1, and one each from Vein Zones 2 and 3)

- feed grades for the six samples assayed between 3.3 and 37.1 g/t gold, and between 12 and 136 g/t silver – see table below for details

- sulphur measured between 0.3 and 0.7%; nearly all as sulphide sulphur

- carbon measured between 0.04 and 0.7%; with low levels of organic carbon (0.03 to 0.04%) with a low percentage as coarse “nugget” gold

- combined flotation recovery and cyanidation extraction of gold ranged from 93 to 98% (average 95%), and for silver from 95 to 98% (average 96%)

- recoveries through an industry standard process flowsheet were comparable for both lower and higher-grade samples, and for each of the three vein zones

Metallurgical Test Programs and Results:

Westhaven prepared six composite samples for preliminary metallurgical work from archived jaw crushed coarse (>70% passing 2mm square mesh sieve) ‘reject’ drill core material associated with routine sampling activities. This crushed drill core should be sufficient for scoping level testing, but there may be some degradation in the performance of the samples during testing. Westhaven has collected additional drill core from the South Zone during 2021 and, once the maiden mineral resource estimate has been completed, this fresh uncrushed core would be available for additional metallurgical testwork beyond scoping levels. Samples ranged from 14.5 to 18.0kg each (combined total of 97 kg), with four composite samples submitted to ALS Metallurgy Kamloops from Vein Zone 1 mineralization, and one each from Vein Zones 2 and 3. Results of two tranches of test work completed in 2021 are compiled in the table and figure below. A point form summary of the two metallurgical test results is also provided.

A table accompanying this announcement is available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/0b983c9d-b43a-42d8-802e-23bb97560b5a

A graph accompanying this announcement is available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/313a6608-8e1c-4f39-ae70-212e485c1ed3

Notes:

- Achieved lengths for samples VnZn1–21 and VnZn2–1933 show a slight difference due to missing coarse reject material. In VnZn1-21 a single 0.35m interval could not be found. Three samples totaling 2.1m length were missing from VnZn2–1933.

- As reported by ALS Metallurgy Kamloops (“ALS”), an ISO 9001:2015 certified testing laboratory.

- Gold head grade in g/t from nominal 500g screened metallic assay as reported by ALS Metallurgy Kamloops.

- Silver head grade from aqua regia digestion (g/t) as reported by ALS Metallurgy Kamloops. Silver head grades were also derived from 4 acid digestion carried out by ALS Geochemistry Vancouver, and agree within a few percentage points.

- Check assays on select sample materials returned from the metallurgical test work, including head feed and concentrates, were submitted by Westhaven to an independent third-party analytical facility whose results support those reported by ALS.

- Primary grind sizing was a nominal 75 micron K80 (80% of material passing through a 75 micron mesh screen).

- Gold and silver recovery percentages are for combined flotation recovery and cyanidation extraction, as reported by ALS Metallurgy Kamloops.

Two tranches of metallurgical testwork were undertaken by ALS Metallurgy Kamloops in 2021. Primary objectives of the first program (KM6326) were to:

- Assess the chemical content of six provided samples through standard chemical assays, screened metallic gold assays, and multi-element ICP analyses.

- Assess the amenability of the gold and silver within the six samples to gravity concentration through laboratory scale Knelson gravity testing with hand panning of the Knelson concentrate.

- Assess the amenability of the gold and silver within the six samples to bulk froth flotation separation through rougher flotation testing.

- Assess the cyanidation extraction potential of gold and silver within the six samples through cyanidation leach extraction bottle roll tests.

The second program (KM6393) was conducted as a follow-up to the initial testing to assess finer primary grind sizings and additional flowsheet configurations using the remaining sample mass. The primary objectives of the second program were to:

- Assess the effect of a finer primary grind sizing on the gold and silver recovery for the six samples using bulk rougher flotation separation.

- Assess the cyanidation extraction potential of gold and silver for the six samples at a finer primary grind sizing through whole ore cyanidation leach extraction bottle roll tests.

- Investigate a flowsheet incorporating bulk froth flotation with cyanidation of the flotation tailings at both primary grind sizings, through cyanidation bottle roll testing on rougher tailings.

Results of the two metallurgical programs are summarized below:

- Screened metallic gold grades for the six feed grades measured between 3.3 and 37.1 g/t.

- Silver content by wet digestion ranged between 12 and 136 g/t.

- Sulphur measured between 0.3 and 0.7 percent; nearly all as sulphide sulphur.

- Carbon measured between 0.04 and 0.7 percent; with low levels of organic carbon (0.03 and 0.04 percent), suggesting that there should not be issues with reagent consumption or gold/silver preg-robbing during a cyanidation leaching procedure.

- Initial investigations used a primary grind sizing of 150um K80, and supplementary work used a 75um K80 grind.

- A Bond ball work index test for a composite prepared from the remaining sample mass of four of the six original samples was calculated at about 20 kWhr/tonne.

- Gravity recovery and screened metallic analyses indicate that there was likely not a presence of coarse “nugget” gold, and that a gravity recovery circuit would not likely be included in mine design.

- Combined flowsheet test results recorded reagent consumptions slightly lower at the coarser primary grind sizing with sodium cyanide consumptions recorded at 0.46 kg/tonne leach feed and lime consumption at about 0.66 kg/tonne leach feed. At the finer primary grind sodium cyanide consumptions averaged about 0.63 kg/tonne leach feed and lime consumption was recorded at about 0.74 kg/tonne leach feed.

- ALS Metallurgy Kamloops concluded that the highest recoveries/extractions of gold and silver were produced through initial rougher flotation with cyanidation leaching of the rougher tailings. At the finer primary grind sizing, the average combined flotation recovery and cyanidation extraction of gold and silver measured 95 and 96 percent, respectively.

Recommendations for future testing include optimization of rougher tailings cyanidation conditions, cyanidation of rougher concentrates, cleaner flotation testing and a more extensive variability program – all of which would require larger masses of feed material – as well as confirming marketability of the final concentrate.

On behalf of the Board of Directors

WESTHAVEN GOLD CORP.

"Gareth Thomas"

Gareth Thomas, President, CEO & Director

Qualified Person Statement

Peter Fischl, P.Geo., who is a Qualified Person within the context of National Instrument 43-101 has read and takes responsibility for this release. Results for the two metallurgical test programs were provided and approved by Robert Sloan, P.Eng, VP ALS Metallurgy Americas, a Qualified Person for the purpose of National Instrument 43-101. Westhaven’s ongoing Quality Assurance and Quality Control programs include auditing of all exploration data. Any significant changes will be reported when available.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

About Westhaven Gold Corp.

Westhaven is a gold-focused exploration company advancing the high-grade discovery on the Shovelnose project in Canada’s newest gold district, the Spences Bridge Gold Belt. Westhaven controls 37,000 hectares (370 square kilometres) with four 100% owned gold properties spread along this underexplored belt. The Shovelnose property is situated off a major highway, near power, rail, large producing mines, and within commuting distance from the city of Merritt, which translates into low-cost exploration.

Westhaven trades on the TSX Venture Exchange under the ticker symbol WHN. For further information, please call 604-681-5558 or visit Westhaven’s website at www.westhavengold.com.